Bearing Basics: A Comprehensive Guide

Bearing basics. What are they? Why do we need to know about them? Unless you work in the engineering or automotive industries, you may not have ever given much thought to bearings. But whether you realize it or not, bearings play a vital role in many of the things we use every day. In this comprehensive guide, we will explore everything you need to know about bearings. From how they work to their different types and uses, by the end of this blog post, you will be an expert on all things bearing related!

What are bearings?

There are many types of bearings, but they all share the same basic principle: to support and constrain relative motion between two parts while reducing friction. Bearings allow rotational or linear movement while supporting loads and reducing friction.

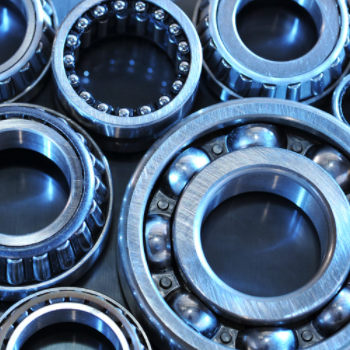

The most common type of bearing is the ball bearing. Ball bearings consist of a series of balls held between two races, or rings. The balls rotate freely between the races, so there is little friction between the parts. Ball bearings are used in a wide variety of applications, from wheels to pulleys to skateboards.

Roller bearings are similar to ball bearings, but they use cylinders instead of balls. Roller bearings can handle higher loads than ball bearings, but they also have more rolling resistance, so they are not as efficient. Roller bearings are often used in heavy-duty industrial applications such as conveyor belts and roller coasters.

There are also several other types of bearings, including needle bearings, thrust bearings, and tapered roller bearings. Each type has its own advantages and disadvantages, so it is important to select the right type of bearing for the application.

Bearings are one of the most essential components in machinery, as they allow smooth and controlled motion between two moving parts. But how do they work? In this article, we'll take a look at the basics of bearing technology, including how they are designed and manufactured.

Bearings work by reducing friction between two moving surfaces. This is done by using a series of small metal balls or rollers that rotate between two circular tracks (known as races). The balls/rollers and races are usually made from hardened steel, which reduces wear and tear.

The size and type of bearing you need will depend on the loads and speeds involved in your application. For example, bearings used in automotive applications must be able to withstand high speeds and heavy loads, whereas those used in smaller electronic devices may only need to deal with lower speeds and lighter loads.

Bearings are typically classified into four main categories: ball bearings, roller bearings, needle bearings, and thrust bearings. Each type has its own unique advantages and disadvantages that make it better suited for certain applications.

Ball bearings are the most common type of bearing and can handle both radial (side-to-side) and thrust (up-and-down) loads. They are often used in electric motors, wheels, and other applications where high speeds and low friction is necessary. Roller bearings can handle higher loads than ball bearings but are not suitable

Different types of bearings

There are three main types of bearings: ball bearings, roller bearings, and thrust bearings. Ball bearings are the most common type of bearing and can handle both radial and thrust loads. Roller bearings can handle heavier radial loads than ball bearings, but they can’t handle thrust loads at all. Thrust bearings are designed to handle only axial (thrust) loads.

Ball Bearings

Ball bearings are the most common type of bearing and can be found in a wide variety of applications. They are available in both single-row and double-row designs. Single-row ball bearings have one row of balls, while double-row ball bearings have two rows. Ball bearings can support both radial and thrust loads, but they’re not designed to handle heavy radial or thrust loads.

Roller Bearings

Roller bearings are available in several different types, including cylindrical, needle, spherical, and tapered. They can support higher radial loads than ball bearings, but they can’t support any thrust loads at all. Roller bearings are used in a wide variety of applications that require high radial load capacity but don’t involve any axial (thrust) loads.

Thrust Bearings

Thrust bearings are designed to handle axial (thrust) loads only; they can’t support any radial loads at all.

There are several advantages and disadvantages to bearings that should be considered before selecting a type of bearing for an application. Some advantages of bearings include the ability to support large loads, absorb vibration and shock, precision-engineered for low noise and long life, and require little maintenance. Disadvantages of bearings can include high initial cost, sensitivity to contamination and lubrication, and potential brittleness at extremely low temperatures.

How to select the right bearing for your application

There are many factors to consider when selecting the right bearing for your application. The following tips will help you choose the best bearing for your needs:

1. Consider the type of load that will be placed on the bearing.

2. Determine the required speed and accuracy for the application.

3. Choose a material that can withstand the operating conditions.

4. Select a bearing size that can support the loads placed on it.

5. Consider any special requirements for the application, such as vibration or shock resistance.

Conclusion

We hope you found this guide on bearings helpful. Bearings are an essential component in many machinery and equipment, so it's important to have a good understanding of how they work. With the right maintenance and care, bearings can last for many years. If you have any questions about bearings or need help finding the right type for your needs, please contact us and we'll be happy to assist you.

After reading this comprehensive guide on bearings, you should now have a good understanding of what they are and how they work. Bearings are an essential part of many machines and devices, and it is important to be familiar with the different types and their applications. With this knowledge, you will be able to select the best type of bearing for your needs and ensure that your machinery runs smoothly.