FAG Bearing

The product spectrum includes rolling and plain bearings, linear and direct drive technology, as well as service features such as maintenance products and monitoring systems.

The Industrial division offers a wide portfolio of bearing solutions, ranging from high-speed and high-precision bearings with small diameters to large-size bearings several meters

wide. Increasingly, the focus here is on smart products and on connecting components.

Schaeffler Solutions for Wind, Rail, Industrial Automation and more

In an increasingly dynamic world, bearings and system solutions from Schaeffler not only help railways prepare for the challenges of the future, but also improve their safety.

Power transmission

Schaeffler solutions for fluid technology, industrial transmission, pneumatics, infrastructure, marine, electric motors, public and private institutions, locks and fittings, and electrical household appliances.

Offroad

Schaeffler solutions for construction machinery, agriculture, industrial trucks, cranes, conveying, elevators, and mobile transmission.

Industrial automation

Schaeffler solutions for printing machines, medical equipment, food and packaging, productronics, textile machinery, machine tools, wood working machinery, rubber and plastics, assembly and parts handling,

and industrial robots.

Raw materials

Schaeffler solutions for metallurgical production and processing, mining and processing, pulp and paper, and drilling and conveying equipment.

Aerospace

In the aerospace sector, the Schaeffler Group is a leading manufacturer of high-precision bearings for aircraft and helicopter engines and for applications in space travel.

Two-wheelers

Schaeffler solutions for LEV, bicycles, and sport, motorcycles and special vehicles, and small combustion engines.

The modular range of courses on offer at our Schaeffler Technology Center – Training is based on the principle of holistic expertise and includes the entire product and service portfolio

while offering all participants the greatest possible range of individual selection and expansion options. This is how each individual acquires the exact knowledge that he requires for his daily work in areas such as design, assembly,

maintenance or purchasing.

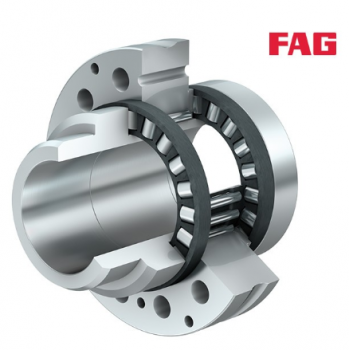

Tapered roller bearings

FAG tapered roller bearings can support high radial and axial loads. They have a broad range of speeds. They are efficient at supporting forces and ensure a precise and rigid shaft guidance system due to

the large effective distance between the bearings. Tapered roller bearings can be adjusted and dismantled, which makes mounting easy.

Tapered roller bearings in X-life quality – reliable and energy efficient with a high load-carrying capacity

Numerous FAG tapered roller bearing series are available in X-life quality. In order to fulfill the requirements of X-life, the geometry, surfaces, dimensional and running accuracy, and the material and

heat treatment process were all optimized. FAG tapered roller bearings in X-life quality increase the overall efficiency of your machines and equipment.

Spherical roller bearings

Delivering an outstanding performance: Spherical roller bearings are designed for systems in which high loads must be supported and shaft flexing and misalignments compensated. They deliver extremely

high performance and are designed to carry extreme loads

The decades of experience our engineers have gathered combined with innovative ideas improve our spherical roller bearings even further. As a matter of fact, our quest for perfection in development and

production ensures optimum kinematics and low wear, which increases the service life even more. And that comes at a low maintenance outlay and minimum maintenance costs.

Needle roller bearings

Needle roller bearings have a long track record as proven machine elements for the design of radially compact bearing arrangements with very high load-carrying capacity. In X-life configuration, they now have

an up to 50 % longer service life.

Cylindrical roller bearings

Single-row cylindrical roller bearings with cage are units comprising solid inner and outer rings and cylindrical roller and cage assemblies. The outer rings have rigid ribs on both sides or no ribs, and the inner rings

have one or two rigid ribs or are designed without ribs. The cage prevents the cylindrical rollers from coming into contact with each other during rolling. Cylindrical roller bearings can be supplied with or without a cage

Barrel roller bearings

Barrel roller bearings are single-row, self-aligning roller bearings. They comprise solid outer rings with a concave raceway, solid inner rings with two ribs and a cylindrical or tapered bore as well as barrel rollers with cages.

The bearings cannot be dismantled.

Barrel roller bearings are particularly suitable where high radial shock type loads occur and misalignments must be compensated; see section on compensation of angular misalignments. They have only a low axial

load-carrying capacity.

FAG deep groove ball bearings are available in radial and axial designs for many different variants.

Single-row deep groove ball bearings are available in open and sealed designs. They are designed for high to very high speeds and can accommodate radial as well as axial forces.

Double-row deep groove ball bearings correspond with single-row deep groove ball bearings in design and are used when the radial load capacity of single-row deep groove ball bearings is insufficient.

FAG axial deep groove ball bearings are available in single or double-direction design variants. These bearings are especially well suited to high axial loads.

Four-point contact ball bearings

Four-point contact bearings are single-row angular contact ball bearings and therefore require significantly less space in an axial direction than double-row designs.

The bearings comprise solid outer rings, split inner rings and ball and cage assemblies with brass or polyamide cages. The two-piece inner rings enable a large complement of

balls to be accommodated. The inner ring halves are matched to the particular bearing and must not be interchanged with those of other bearings of the same size. The outer ring

with the ball and cage assembly can be mounted separately from the two inner ring halves.

Self-aligning ball bearings

Self-aligning ball bearings are double row, self-retaining units comprising outer rings with a concave raceway, inner rings with a cylindrical or tapered bore and ball and cage assemblies.

Spindle bearings

Spindle bearings are single-row angular contact ball bearings comprising solid inner and outer rings and ball and cage assemblies with solid window cages. They cannot be dismantled.

The bearings are available in open and sealed designs.

Spindle bearings have restricted tolerances. They are particularly suitable for bearing arrangements with very high requirements for guidance accuracy and suitability for high speeds.

They have proven ideal for spindle bearing arrangements in machine tools.

Thin section bearings

Thin-section bearings are high-precision products with very little running noise and a high load-carrying capacity. These bearings are available in three different designs with extremely small,

predominantly square cross-sections. Within each series, the cross-section remains constant even in the case of larger shaft and housing bore diameters. The bearings are therefore also described

as constant section (CS) bearings. This feature distinguishes thin section bearings from the conventional bearings that are described in standardized ISO series.

Screw drive bearing arrangements are subjected to requirements that often cannot be optimally fulfilled by the design construction of conventional bearings. In order to configure bearing arrangements for

the highly dynamic operating conditions in screw drives with high accuracy, high load-carrying capacity, high rigidity, low friction, easy fit and maintenance-free or low-maintenance design, INA/FAG has a wide

range of axial angular contact ball bearings. With this well thought-out product range, ideal application-specific solutions can now be found for all the technical and economic demands placed on the bearing

arrangements of screw drives.

Crossed roller bearing

Crossed-roller bearings are bearings for high-precision applications whose dimensions conform to ISO dimension series 18 as per DIN 616. They comprise outer rings, inner rings, rolling elements and plastic spacers.

The outer ring is split and is held together by three retaining rings.

Due to the X arrangement of the cylindrical rollers, these bearings can support axial forces from both directions as well as radial forces, tilting moment loads and any combination of loads by means of a single

bearing position. As a result, designs involving two bearing positions can be reduced to a single bearing position. Crossed roller bearings are very rigid, have high running accuracy and are supplied with normal clearance,

low clearance or preload. The bearing outer rings are easily fixed to the adjacent construction using clamping rings.

Rotary table bearings

Axial-radial bearings are double-direction axial bearings for screw mounting with a radial guidance bearing. These ready-to-fit, pregreased units are very rigid, have high load-carrying capacity and operate with particularly

high accuracy. They can support radial forces, axial forces from both directions and tilting moments free from clearance. ZKLDF axial angular contact ball bearings are low-friction, ready-to-fit, greased bearing units with high

accuracy for very high speeds, high axial and radial loads and high demands on tilting rigidity. Axial-radial bearings with angular measuring system YRTM and YRTSM correspond in mechanical terms to series YRT and YRTS

but are additionally fitted with an angular measuring system.

Slewing rings

INA slewing rings are known worldwide as premium products in the field of rolling bearing technology. These machine elements have proven themselves many times over; they have high loadcarrying capacity, a versatile range

of applications and are highly cost-effective. Due to their design, a single bearing can reliably support radial, axial and tilting moment loads. It is therefore possible in many cases to replace bearing arrangements comprising a

combination of radial and axial bearings by a single bearing. This reduces ─ in some cases considerably ─ the costs and work required in the design of the adjacent construction and the fitting of bearings.

Slewing rings are sealed on both sides, lubricated with a high-quality grease, can be relubricated via lubrication nipples and are particularly easy to fit. The bearing rings are supplied without gear teeth or, in order to achieve

simple drive solutions, are available with external or internal gear teeth.

INA slewing rings are designed as four-point contact bearings and as Crossed roller bearing.

Track rollers, backup rollers and cam rollers

Ball bearing track rollers are self-retaining, single or double-row ball bearings with particularly thick-walled outer rings. In addition to high radial forces, these bearings can also support axial forces in both directions.

Yoke-type track rollers are single or double-row units mounted on shafts or studs. They comprise thick-walled outer rings with a profiled outside surface and needle roller and cage assemblies or full-complement rolling

element sets.

Cam rollers are similar in their construction to single and double-row support rollers, except that the raceway is formed by a heavy-section roller stud with a fixing thread and lubrication hole.

Proven application areas for these products include cam mechanisms, guideways, conveying systems and linear guidance systems.